I cut the top to length after glue up is done. There will be two 2 1/4" wide breadboard ends, each with three 1 1/2" deep mortises and a continuous 3/4" deep groove. They will overhang the sides 3/4", so I cut the top to the outside length of the front.

Now I lay out the pieces for the breadboard ends. I am making them a bit thick and will plane them even after the breadboard ends are glued on.

There will be three mortises in each end as well as a groove.

I mark the start and end points for mortising,

then transfer the marks to the top.

I check the set up one last time and I make the mortises.

I then run the groove using the dado head on the table saw. I set it up so I would make two passes, one each side. That will give me a perfectly centered groove that lines up with the mortises.

As I push the piece through the saw I can feel the resistance lessen as the dado head enters each mortise. It is rewarding to also hear that the dado head is not cutting anything when it passes through the mortise. My set up is right on.

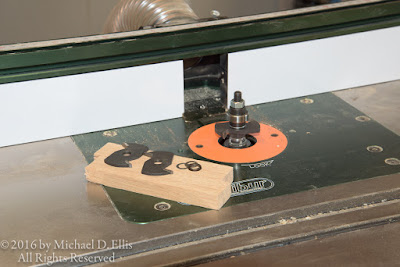

Now I set up the router table to cut the tenons for the breadboard ends. I put the largest rabbet bit I have (3/4") in the collet.

It will take three passes each side to cut the tenons and tongue this way but I don't want to use the dado head or run something this large through the table saw on end. I make a few test cuts with the offcuts of the top and then I have at it.

I am using a backer block to keep the back side from blowing out when the bit comes through. It's on top of the board in the photo below as I need that hand when I start the cut. This isn't as awkward as it looks. While more table in front would be nice, the table

is wide enough to register on.

With tenon length cut I mark the locations of the rip cuts from the mortises in the breadboard ends. I used a jig saw to make these cuts. The scrap piece keeps the baseplate of the jigsaw off the work.

The crosscuts are also made with the jigsaw, except for the ends. I cut them a bit long and I'll trim them with a chisel after I get the tenons fit.

I must have let the top drift a little on one side when I was routing the tenons. I should have used a featherboard somehow to hold it down.

It's not much, about a 32nd of an inch, in the middle. I'll use my shoulder plane to fix that.

The tenons are too tight so again with the shoulder plane.

And after some more fussing around the breadboard ends are fitted and ready to glue.

I'll get this glued up but I want to get the top surfaced for finish first. Then I can plane the BB ends down to the level of the top and not have to try to work up to crossgrain. When your tool is sharp it is a delight to use hand planes.

Thanks for taking a look. There's more to come so check back soon!