This project started with a few nice pieces of ash. I had the material left over from a past project and had been looking at the pretty quarter sawn grain that could come from them. These pieces were about 4" X 6" X 36" long. By re sawing I could come up with quarter sawn material for the top and apron, and rift sawn material for the legs. I started designing a small table with drawers several years ago to be made from this ash. I finally started building this table a year or more ago. I made the top but was still making design decisions about the legs and placement of drawers. Other things came up and needed doing so I never got farther than blanking out the material for legs, apron and frame parts. Well, the time to finish that project has come.

The top has already been finished with 3 coats of Tried and True Varnish Oil followed by 3 coats of wax.

The other material has been stickered on the lumber rack rack waiting for me to get back to it.

Here is a basic drawing of the table.

I decided to make the legs with a double taper, a design I have used before and like. I will also have a drawer in each of the narrow ends of the table. Since the drawers will be full height the stretchers will be concealed behind the drawer front. The joinery at the top of the leg is shown in plan view in the drawing below.

Well, I'll be getting started on this table soon, but I need to make a leg tapering jig first. More about that next time. Thanks for taking a look and leave a comment if you want to. I like to think people are reading this but it would be nice to have some verification!

Showing posts with label joinery. Show all posts

Showing posts with label joinery. Show all posts

Thursday, December 22, 2016

Monday, September 12, 2016

Blanket Chest Joinery

With the walnut lumber having sat now for almost a month since being cut open, I can bring this material to dimension. I had to flatten everything again and then plane to thickness. I used the table saw to rip to width, and a cut off sled to make the crosscuts. Now I need to get ready to cut the joinery.

For the legs I need to cut mortises with grooves between, as well as the "foot" detail. Here is my shop drawing of a leg as well as a plan view detail and an elevation detail of the bottom rail joinery.

I started checking dimensions for the cutters I wanted to use and found my 1/4" hollow chisel mortise bit is slightly larger (about 15/1000s) than 1/4". The slot cutter can make that dimension for a tongue and a groove but I will need to do some test cut first.

For the legs I need to cut mortises with grooves between, as well as the "foot" detail. Here is my shop drawing of a leg as well as a plan view detail and an elevation detail of the bottom rail joinery.

A few details may change as I am still thinking through where the floor seats in a groove in the bottom rails. I want to also seat the floor into the legs and am also thinking of rabbeting the inside of the leg flush with the inside of the rails. Mainly I am thinking about whether this will remove too much material and compromise strength and stability.

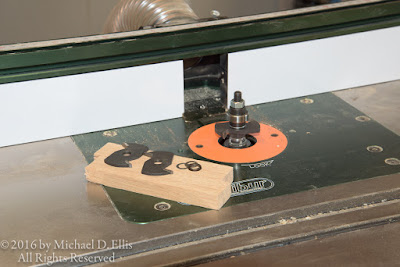

I recently purchased a set of slot cutters for the router and am planning on using them to cut the tongues and grooves for this project. This set (from Lee Valley tools) includes a variety of shims to adjust the width of the tongue or groove. It includes a pretty comprehensive set of instructions.

I started checking dimensions for the cutters I wanted to use and found my 1/4" hollow chisel mortise bit is slightly larger (about 15/1000s) than 1/4". The slot cutter can make that dimension for a tongue and a groove but I will need to do some test cut first.

I am using a new bit for my mortise machine and as you can see, the drill bit shank is too long and needs to be "docked".

I want to do a neat job so I make a holder of hardwood by drilling a hole the size of the bit shank in a block and sawing it in half. I can then put the bit in the hollows and clamp the block. This gives me something I can clamp in a vise or hold on to while I hacksaw the bit to length.

I have a few different sized holes in this block. I also have a block sized for a 1/2 inch bit. I run the hacksaw against the side of the block and use a file after to smooth the cut.

Now I can make a test mortise and size the winged cutters for a test groove.

I am pleased with the results using the mortise machine and the winged cutters. I was able to size the groove to fit the mortise and, in two tries, line the mortise up with the groove cutters.

Next time, more joinery details.

Monday, June 27, 2016

Hand Tools

Hand tools certainly have their place in the custom woodworking shop. Power tools accomplish many tasks quickly and efficiently and are a boon to the woodworker, resulting in savings of time as well as saving your body from physical degradation. I want to produce work that I am satisfied making and that people can afford to buy. Besides, running those hand tools is really hard, time consuming work. There are however, many situations where hand tools provide the best and most accurate result.

I enjoy using hand planes, chisels and saws but if I was restricted to hand tools I wouldn’t be able to get much done and I would have to start working out to develop the muscles and stamina to spend 8 hours a day running a hand saw or plane. I think there is a balance to be struck between one extreme and the other. It makes sense to me to do as much of the work as possible with power tools and to use hand tools where they provide the best solution to a problem.

In general this means that sizing of timber is done on the bandsaw, flattening the face and squaring the edge are done on the jointer, and final dimensioning is accomplished with the planer and/or table saw. There are times however, when it is easier to plane an edge by hand or to cut and plane with hand tools, mainly on real ornery or very small pieces. This gets the material to a workable state in an efficient manner.

From this point I decide what tool to use based on efficiency versus accuracy, quality and esthetics. I use power tools to cut joinery within the parameters of quality I am trying to achieve, and then use hand tools for final fitting of the joint. I usually make mortise and tenon joints by machine, then use chisel and plane for final fitting.

For dovetails, I often cut the tails partially on the table saw if layout allows. I then use a chisel to remove the waste. After laying out the pins from the tail board, I use a hand saw to cut them out and chisel to remove the waste. This procedure produces a nice fitting joint for me .

For dovetails, I often cut the tails partially on the table saw if layout allows. I then use a chisel to remove the waste. After laying out the pins from the tail board, I use a hand saw to cut them out and chisel to remove the waste. This procedure produces a nice fitting joint for me .

I have found that other joints, like tapered sliding dovetails and finger joints are best done with machines, jigs, and as much accuracy as you can possibly manage. Other joinery methods which find a use in my shop from time to time include plate joinery, dowels and slip tenons. I try to find the most efficient method for each task that will accomplish the structural, esthetic and economic goals I have set for the piece. This results in a project that, to me, achieves the quality I want to produce without breaking the budget for a piece.

Subscribe to:

Posts (Atom)